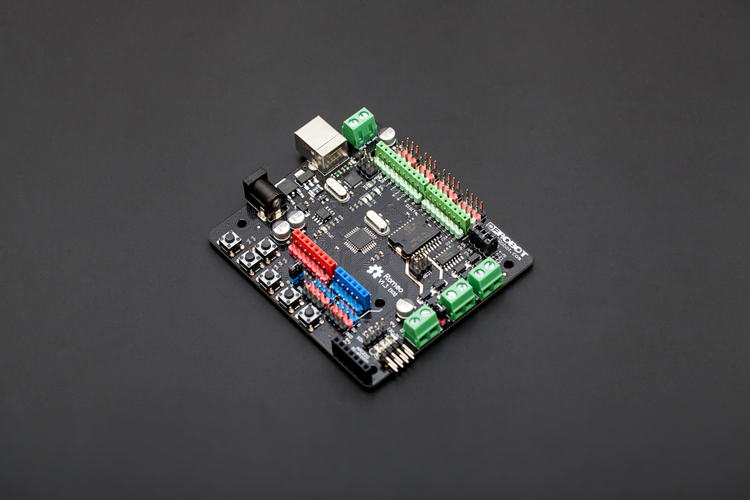

INNFOS Robot Control Board Revolutionizing Robotics with Smart Control Systems

In the field of robotics, a control board is the central unit that orchestrates the operations of a robotic system. The control board acts as the brain, commanding motors, sensors, and other components to perform specific tasks, whether it’s in manufacturing, education, or research. One such innovative technology that has made significant strides in robotics is the INNFOS Robot Control Board, which is central to the performance and functionality of robotic systems, particularly the company’s modular robotic arms.

This article will explore the features, technology, and applications of the INNFOS Robot Board, its role in advancing robotic capabilities, and how it integrates with various components to deliver seamless operations. We will also dive into how this control board contributes to robotic control, the future of robotics, and the evolution of intelligent robotic systems.

Introduction to innfos robot control board

INNFOS is an emerging player in the robotics industry known for creating high-precision and flexible robotic systems. With a strong emphasis on innovation, the company has developed multiple solutions for both consumer and industrial applications. Among their key products is the INNFOS Robot Control , which powers their smart robotic systems, such as the Gluon robotic arm.

The INNFOS Robot Control Board is engineered with cutting-edge technology, enabling advanced motion control, real-time adjustments, and integrated communication with various robotic components. It serves as the interface between the robotic hardware (like sensors, motors, and actuators) and the software controlling the system’s behavior.

The Importance of a Robot Control Board

A robot control board plays a pivotal role in ensuring the efficiency, precision, and functionality of a robot. It acts as the brain, processing inputs from the sensors and commanding the actuators and motors. In advanced robotic systems, the control board must be versatile enough to handle complex tasks, including movement coordination, feedback processing, communication with external devices, and adaptive learning.

For robotics to be effective in real-world applications, such as manufacturing automation, educational tools, or autonomous vehicles, the control board must provide:

High Precision: For robots to perform tasks accurately, especially in assembly lines or medical applications.

Real-Time Communication: The control board should offer quick processing speeds to interact with sensors and actuators instantaneously.

Modularity and Flexibility: Innfos robot control board ability to adapt to different tasks often requires a flexible control system capable of integration with multiple peripherals, making modularity essential.

Ease of Programming: Developers need intuitive programming interfaces to configure, control, and update robots for various functions.

INNFOS’s approach addresses these requirements, ensuring that their robot control boards are both powerful and user-friendly.

Key Features of the INNFOS Robot Control Board

INNFOS has developed several generations of robot control boards, each equipped with sophisticated features to enhance robotics applications. The INNFOS Robot Board is not just a simple controller; it is a comprehensive solution that integrates multiple technologies to provide precision and flexibility. Some of the key features include:

High-Precision Motion Control

The INNFOS Robot Control is equipped with advanced motion control algorithms that ensure smooth, precise, and coordinated movements. This precision is vital for tasks such as pick-and-place operations, robotic surgery, and other applications requiring minute adjustments.

The board supports high-precision actuators, which can move with pinpoint accuracy. In combination with feedback systems, such as encoders and force sensors, the control board can make real-time adjustments to the robot’s motion, compensating for any deviation caused by load changes or environmental factors.

Modular Design

One of the defining features of INNFOS’s robotic systems is their modularity. The control board allows for flexible integration with a wide range of components and peripherals. Users can easily swap out end effectors, such as grippers, suction cups, or specialized tools, based on the task at hand. This modular approach enhances the robot’s versatility and expands its potential applications.

For example, the Gluon robotic arm, powered by the INNFOS control board, can adapt to a variety of tasks by swapping the grippers or tools. This ability to customize the robot’s end-effectors opens up possibilities in industries like logistics, education, and research.

Smart Compliant Actuators innfos robot control board

INNFOS utilizes its proprietary Smart Compliant Actuators (SCA) in conjunction with the robot control board. These actuators combine the benefits of precise motion control with inherent flexibility, allowing the robot to perform more dynamic movements. This makes it particularly well-suited for collaborative tasks with humans, such as in environments that require both flexibility and precision.

The SCA technology also allows the robot to “feel” its environment and adjust its movements accordingly, enhancing its ability to handle delicate or unpredictable tasks, such as handling fragile objects or operating in cluttered environments.

Advanced Safety Mechanisms

Robotic safety is a crucial aspect of modern automation. The INNFOS Robot Board features advanced safety protocols, including collision detection and emergency stop systems. Using real-time feedback from sensors and encoders, the control board can detect any unexpected force or obstacle in the robot’s path and stop the motion to prevent damage or injury.

Additionally, the board supports safety protocols for working in collaborative environments, where robots interact directly with human workers. With proper sensor integration, it ensures that the robot can halt operations when detecting the presence of humans in proximity.

Real-Time Processing and Feedback

The INNFOS Robot Control Board excels in processing data from multiple sensors in real time. This is essential for robots performing tasks that require immediate responses, such as in automated assembly lines or dynamic environments where conditions change rapidly. Adjusts outputs accordingly, and ensures that the robot performs actions that are accurate and safe.

Feedback mechanisms, such as force and position sensors, are crucial to maintain operational integrity. The control board ensures that the robot adapts to varying environmental conditions while maintaining performance consistency.

Cross-Platform Compatibility

The INNFOS Robot Board supports a variety of programming languages and software environments. It can be easily integrated with different operating systems, such as Windows, Linux, and macOS, making it accessible to a wide range of developers. INNFOS provides a Software Development Kit (SDK) that allows users to customize the robot’s operations and develop specific applications for their use cases.

This flexibility makes the INNFOS Robot Board suitable for a wide range of industries, from academic research to industrial automation and robotic manufacturing.

Applications of the INNFOS Robot Control Board

The versatility of the INNFOS Robot Control enables its use across a broad spectrum of industries and use cases. Some of the primary applications of the INNFOS robot control systems include:

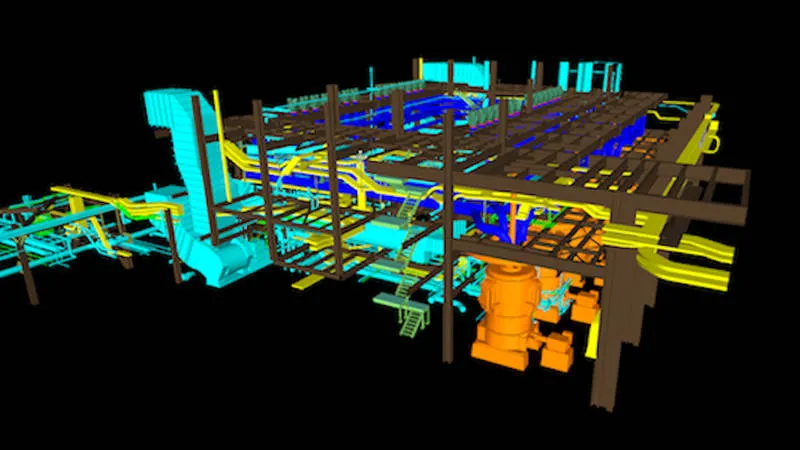

Industrial Automation

In manufacturing, the INNFOS Robot Control plays a pivotal role in automating repetitive tasks such as assembly, inspection, and packaging. The precision and real-time feedback systems allow robots to handle delicate operations, like placing small components onto circuit boards or assembling intricate mechanical parts.

Educational Robotics

INNFOS’s modular approach makes it an excellent choice for educational robotics. The simplicity of the control board combined with advanced features like real-time processing and modular design enables students and researchers to experiment with different robot configurations. In academic settings, the INNFOS robot systems are often used to teach concepts of automation, robotics, and engineering.

Healthcare Robotics

In healthcare, precision is paramount. The INNFOS Robot Control Board supports medical robotics applications like surgery-assisting robots, rehabilitation devices, and patient monitoring systems. Its fine motion control and compliance technology allow robots to interact gently with patients, ensuring safety while delivering precise actions.

Service Robots

Service robots, from delivery bots in hospitals to robots assisting in customer service, rely on the INNFOS Robot Control for their flexible control systems. The board helps service robots navigate complex environments, interact with humans, and perform various tasks like transporting goods or providing information.

Research and Development

In research environments, the INNFOS Robot Control is widely used for experimentation. Its modularity and adaptability make it ideal for researchers developing new robotics concepts, testing different sensors, and exploring the potential of autonomous robots.

The Future of innfos robot control board

The future of robotics looks incredibly promising, and the INNFOS Robot Control plays a crucial role in shaping this future. As technology advances, we expect to see even more intelligent, adaptable, and collaborative robots.

Artificial Intelligence Integration

The integration of AI and machine learning algorithms with the INNFOS Robot Board will enable robots to learn from their environments and improve their performance over time. Robots will be able to handle more complex tasks, make decisions autonomously, and interact more naturally with humans.

Expanded Collaboration with Humans

The ability to collaborate safely with humans will continue to be a major focus for robotics. The INNFOS Robot Control compliance and safety features make it well-suited for environments where robots and humans work side by side. Future improvements may enable even more advanced collaborative capabilities, such as robots learning from human actions and adjusting their behavior accordingly.

Smarter, More Efficient Manufacturing

The ongoing evolution of robotics, powered by advanced control systems like those from INNFOS, promises to bring smarter, more efficient manufacturing solutions. These robots will be able to handle increasingly complex tasks, enhance production capabilities, and offer new solutions for industries ranging from automotive to electronics.

Conclusion

The INNFOS Robot Control Board represents a major advancement in robotics, offering precise, flexible, and intelligent solutions for a wide range of applications. Its features, such as modularity, real-time feedback processing, and advanced safety systems, make it an ideal choice for both industrial and academic use.

With continued advancements in AI, automation, and human-robot collaboration, the future of robotics will likely be shaped by the continued development and integration of control systems like those developed by INNFOS. As the technology continues to evolve, we can expect even more sophisticated, autonomous, and intelligent robots, pushing the boundaries of what is possible in industries across the globe.

Post Comment