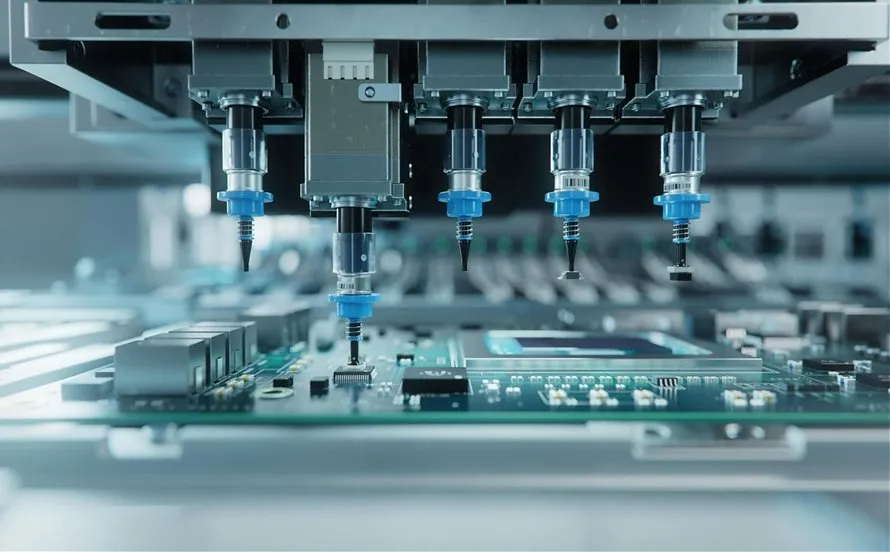

How to Optimize PCB Fabrication and Assembly for Advanced Applications

Printed Circuit Boards (PCBs) are the backbone of modern electronics, powering everything from telecommunications devices to robotics. As industries demand more advanced and efficient electronic solutions, manufacturers must innovate to meet these needs. In this guide, we explore how to optimize PCB fabrication and assembly for advanced applications, focusing on cutting-edge solutions like Rigid-Flex and High-Frequency PCBs.

Understanding the Basics of PCB Fabrication

PCB fabrication involves the design and creation of circuit boards that connect electronic components. The process includes:

- Designing the Layout: Engineers use software tools to design PCB layouts, specifying layer arrangements, component placements, and routing paths.

- Material Selection: The choice of materials, such as FR4, Rogers, or Polyimide, affects performance, particularly in high-frequency applications.

- Patterning and Etching: Conductive materials like copper are patterned to form electrical pathways.

- Drilling and Plating: Vias are drilled and plated to enable electrical connections between layers.

- Quality Testing: Completed boards undergo rigorous testing to ensure reliability.

By collaborating with experienced manufacturers like Global Well PCBA, businesses can ensure high-quality PCB fabrication tailored to their specific needs.

Advancements in PCB Technologies

Modern PCBs are evolving to meet the challenges of advanced industries. Here are some notable advancements:

Rigid-Flex PCBs

- What Are They?: These are hybrid boards combining rigid and flexible substrates, offering design versatility and durability.

- Applications: Ideal for compact devices, medical instruments, and aerospace technologies where space and reliability are critical.

- Advantages:

- Reduces the need for connectors and cables.

- Enhances mechanical stability.

- Improves signal integrity.

High-Frequency PCBs

- What Are They?: These PCBs are designed to handle high-speed signals with minimal loss.

- Applications: Widely used in telecommunications, radar systems, and high-performance computing.

- Advantages:

- Superior dielectric properties.

- Reduced signal attenuation.

- High thermal resistance.

By leveraging these technologies, manufacturers can create efficient and reliable solutions for cutting-edge applications.

Key Considerations for PCB Assembly

PCB assembly involves mounting electronic components onto the fabricated board. Here are some factors to optimize this process:

Component Placement and Orientation

- Proper placement minimizes signal interference and enhances performance.

- Orientation affects solder joint reliability, especially for surface-mounted devices.

Soldering Techniques

- Advanced techniques like reflow soldering ensure precise and reliable connections.

- Using high-quality solder materials reduces defects.

Testing and Inspection

- Automated Optical Inspection (AOI) and X-ray inspection help identify issues like solder joint defects or misaligned components.

Working with a skilled PCBA manufacturer like Global Well PCBA ensures that every step of assembly is meticulously executed, leading to superior end products.

Applications in Telecommunications and Robotics

The demand for advanced PCBs is surging in industries like telecommunications and robotics. Here’s how these sectors benefit:

Telecommunications

- High-frequency PCBs enable faster and more reliable data transmission.

- Applications include 5G infrastructure, satellite communications, and signal amplifiers.

Robotics

- Rigid-Flex PCBs are integral to compact, flexible robotic designs.

- They enhance connectivity in robotic arms, drones, and autonomous vehicles.

These applications showcase the critical role of innovative PCB solutions in driving technological advancements.

Partnering with the Right Manufacturer

Selecting the right manufacturing partner is essential for achieving optimal results. Global Well PCBA stands out with its expertise in advanced PCB solutions and commitment to quality. Here’s what makes them a preferred choice:

- Comprehensive Services: From PCB design to assembly, they handle every stage with precision.

- Advanced Capabilities: Specializing in Rigid-Flex and High-Frequency PCBs, they cater to diverse industry needs.

- Global Reach: As a trusted name in PCB manufacturing, they serve clients worldwide.

To learn more about their offerings and how they can support your projects, visit globalwellpcba.com.

Conclusion

Optimizing PCB fabrication and assembly is crucial for meeting the demands of advanced industries like telecommunications and robotics. By embracing technologies like Rigid-Flex and High-Frequency PCBs and partnering with experienced manufacturers such as Global Well PCBA, businesses can achieve innovative and reliable electronic solutions. Whether you’re developing next-gen communication systems or groundbreaking robotic designs, the right PCB solutions can make all the difference.

Post Comment