How to Improve Industrial Efficiency with Machine Vision Technology

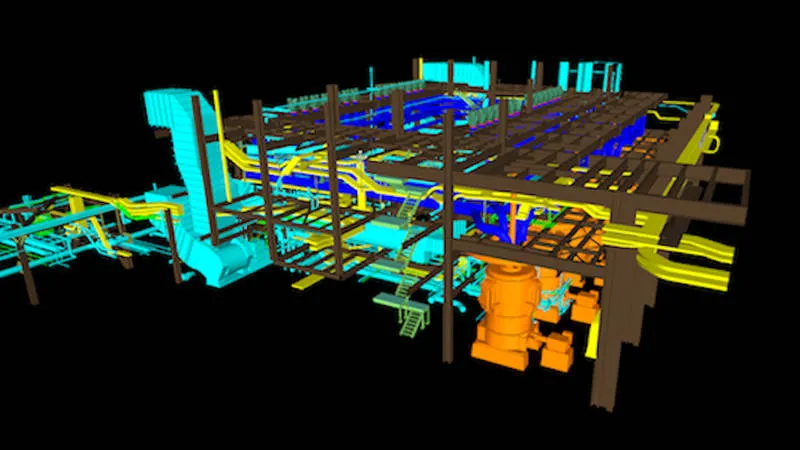

In today’s fast-paced industrial landscape, manufacturers and businesses are constantly looking for ways to improve efficiency, enhance quality control, and reduce costs. One of the most transformative solutions is machine vision technology, which combines high-quality cameras, specialized lenses, and advanced lighting systems to automate inspection and monitoring processes.

Understanding Machine Vision Technology

Machine vision refers to the ability of industrial systems to process and analyze images to make automated decisions. These systems include cameras, lenses, image-processing software, and lighting solutions that work together to capture and interpret visual information.

With advancements in computer vision, industries such as manufacturing, automotive, electronics, and pharmaceuticals are leveraging this technology to enhance quality control, optimize production lines, and reduce human error.

Key Benefits of Machine Vision Technology

1. Enhanced Quality Control

Traditional inspection methods rely heavily on human observation, which can lead to inconsistencies and errors. Machine vision systems, however, provide highly accurate, repeatable, and objective quality checks. By integrating high-resolution cameras and precision lenses, businesses can detect even the smallest defects in products.

2. Increased Production Speed

Machine vision technology enables real-time inspection and monitoring of production lines. With automated defect detection and process optimization, manufacturers can significantly increase production speed without compromising quality.

3. Cost Reduction

By minimizing the need for manual inspection, companies can reduce labor costs and improve overall efficiency. Additionally, early defect detection helps prevent costly recalls and product waste.

4. Better Compliance with Industry Standards

Industries such as pharmaceuticals and food processing must comply with strict quality and safety standards. Machine vision ensures that products meet regulatory requirements by providing detailed and consistent inspection processes.

5. Improved Safety and Reliability

Automated inspection systems reduce the risk of workplace accidents by minimizing human involvement in potentially hazardous tasks. High-performance industrial cameras and lighting solutions ensure optimal visibility even in challenging environments.

How VA Imaging is Revolutionizing Machine Vision

VA Imaging is a leader in industrial machine vision equipment, offering state-of-the-art cameras, lenses, and lighting solutions designed to meet the specific needs of different industries. Their specialized lenses and custom lighting solutions provide superior image clarity and precision, making them a go-to choice for manufacturers looking to improve efficiency and accuracy.

Specialized Lenses for Precision Imaging

VA Imaging’s lenses are engineered to deliver exceptional image quality, even in low-light or high-speed environments. These lenses help businesses capture intricate details, ensuring thorough and accurate inspections.

Advanced Lighting Solutions

Proper lighting is critical for machine vision systems, and VA Imaging offers customized lighting solutions to optimize image capture. Whether it’s high-intensity LED lighting or specialized illumination for specific applications, VA Imaging ensures that their products enhance visibility and contrast for better inspection results.

Affordable and Scalable Solutions

One of the biggest challenges industries face is the high cost of machine vision systems. VA Imaging addresses this by providing affordable yet high-quality solutions, making machine vision accessible to businesses of all sizes.

Industries Benefiting from Machine Vision Technology

Manufacturing

Machine vision enhances assembly line efficiency by automating defect detection and process optimization.

Automotive

Ensures precision in parts manufacturing, welding inspection, and assembly verification.

Electronics

Used for PCB inspection, component placement verification, and soldering quality checks.

Pharmaceuticals

Ensures packaging integrity, label verification, and contaminant detection for compliance.

Food & Beverage

Helps in identifying defects, monitoring packaging quality, and ensuring food safety.

Conclusion

Machine vision technology is revolutionizing industrial efficiency by enhancing quality control, reducing costs, and improving production speed. Companies like VA Imaging are at the forefront of this transformation, providing high-quality, affordable machine vision solutions tailored to various industries.

By investing in custom lenses, advanced cameras, and innovative lighting solutions, businesses can gain a competitive edge and ensure flawless product quality. To explore the latest in machine vision technology, visit VA Imaging.

Post Comment