The accuracy of inspections is critical in industries where precision and compliance are non-negotiable. Traditional inspection methods often rely on manual measurements, which can be time-consuming and prone to human error. With advancements in technology, 3D Scanning Services are revolutionizing the way inspections are conducted, bridging the gap between as-built and as-designed conditions.

The Importance of Accurate Inspections

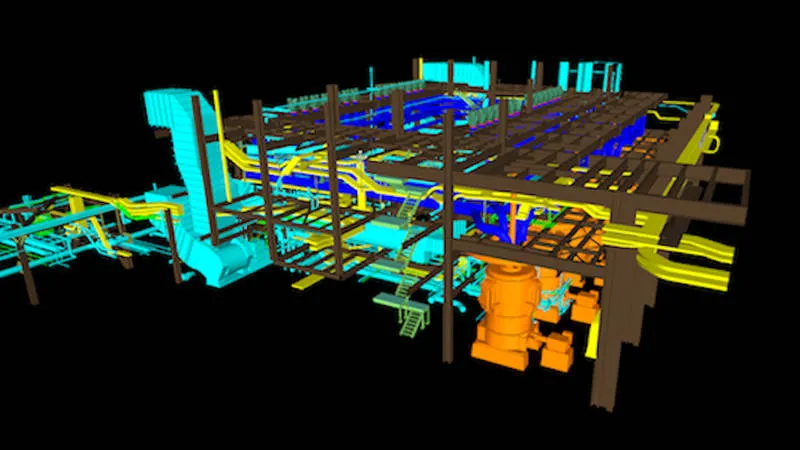

Whether in construction, manufacturing, or infrastructure maintenance, discrepancies between as-built and as-designed models can lead to costly errors, delays, and safety risks. 3D scanning technology provides an efficient solution by offering highly accurate, real-time data to compare actual conditions with design specifications.

Benefits of 3D Scanning in Inspections

- Precision and Accuracy

- Captures complex geometries with millimeter-level accuracy.

- Reduces human error in measurements and documentation.

- Time and Cost Efficiency

- Speeds up the inspection process by quickly scanning large areas.

- Minimizes downtime by allowing real-time analysis.

- Enhanced Documentation

- Creates digital records for future reference and maintenance planning.

- Provides a 3D visual representation for better decision-making.

- Improved Compliance and Safety

- Identifies potential issues before they become critical problems.

- Ensures structures meet industry regulations and standards.

How 3D Scanning Bridges As-Built and As-Designed Models

1. Capturing Reality in High Detail

3D scanners create highly detailed point clouds that accurately represent the physical structure, allowing inspectors to compare these scans with original design specifications.

2. Detecting Deviations Early

By overlaying as-built scans with as-designed models, deviations can be detected immediately, preventing costly modifications later in the project lifecycle.

3. Enhancing Quality Control

Real-time scanning data helps ensure that components are installed correctly, reducing rework and improving overall project quality.

Industries Benefiting from 3D Scanning Inspections

- Construction – Ensures structural elements align with design blueprints.

- Manufacturing – Validates part dimensions for quality assurance.

- Oil & Gas – Inspects pipelines and storage tanks for potential defects.

- Infrastructure – Assesses bridges, roads, and tunnels for maintenance needs.

Why Choose Kova Engineering for 3D Scanning Services?

- Cutting-Edge Technology – We use the latest 3D scanning tools for unmatched accuracy.

- Expert Analysis – Our experienced team interprets data to provide actionable insights.

- Comprehensive Solutions – From inspections to design verification, we cover all aspects of 3D scanning applications.

- Industry Compliance – We ensure all scanning procedures align with regulatory standards.

Conclusion

3D scanning is transforming inspections by providing an accurate, efficient, and data-driven approach to comparing as-built and as-designed conditions. At Kova Engineering (Saskatchewan) Ltd., our 3D Scanning Services help industries achieve higher accuracy, reduce risks, and improve compliance. Contact us today to learn how we can support your inspection needs with cutting-edge technology.