Ram Flywheel 2518 Pilot Bearing Replacement An In-Depth Guide

Ram flywheel 2518 pilot bearing replacement in your Ram truck, specifically the 2518 model with the Cummins diesel engine, is an important yet often overlooked maintenance task. The pilot bearing helps support the input shaft of your transmission, ensuring smooth operation. When it wears out, it can cause vibrations, difficult shifting, and even lead to transmission failure. This article will guide you through the process of replacing the pilot bearing, helping you ensure your truck runs efficiently for years to come.

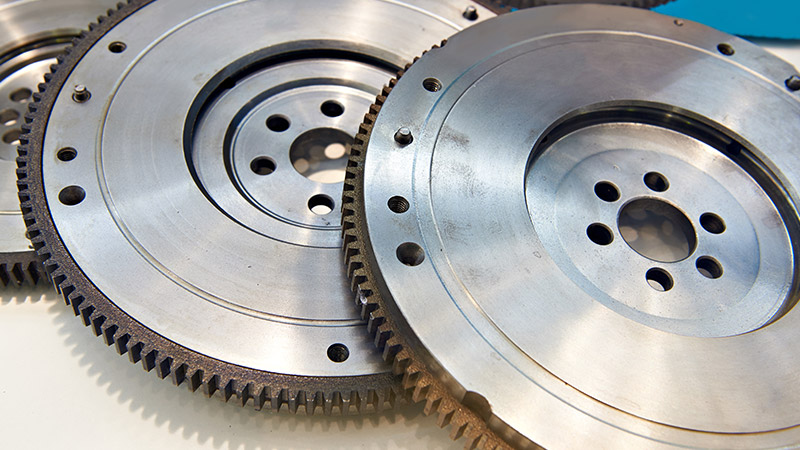

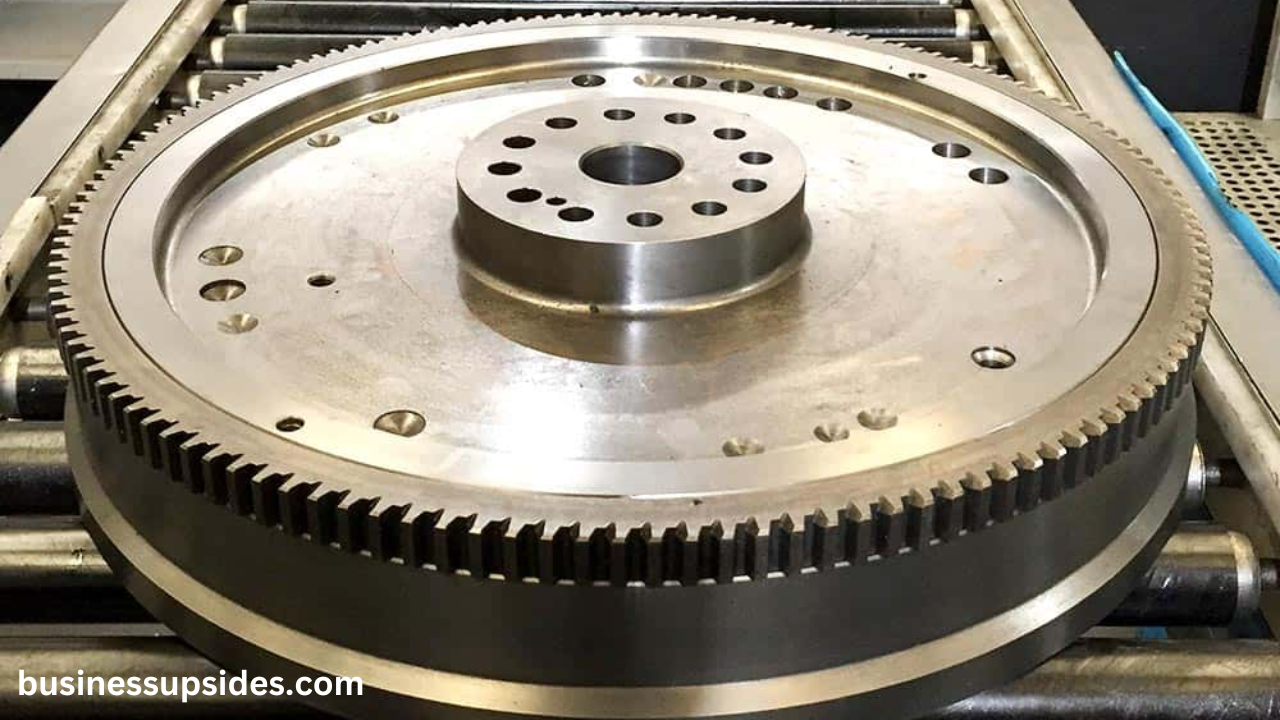

What is ram flywheel 2518 pilot bearing replacement?

A pilot bearing is a small but crucial component located in the flywheel of a vehicle with a manual transmission. Its primary function is to support the input shaft of the transmission, keeping it properly aligned with the engine’s crankshaft. The bearing allows the transmission to spin freely while reducing friction and wear between the rotating components. Without a properly functioning pilot bearing, the transmission could experience significant misalignment, resulting in rough shifting, excessive vibrations, and ultimately, costly repairs.

In the case of the ram flywheel 2518 pilot bearing replacement, equipped with a Cummins engine, the pilot bearing is just as essential. As with any heavy-duty vehicle, the stresses placed on the drivetrain can wear out the bearing over time. A worn or damaged pilot bearing should be replaced promptly to avoid long-term damage to other drivetrain components.

Why Replace the Pilot Bearing?

Over time, pilot bearings wear down due to friction and continuous use. This is especially true in vehicles like the Ram 2518, which often see high-mileage usage or heavy-duty operations. The main reasons to replace the pilot bearing include:

- Normal Wear and Tear: As the bearing operates, it naturally wears out. This is especially true for high-mileage vehicles.

- Symptoms of Damage: A pilot bearing that has become worn or damaged can cause issues such as:

- Grinding or squealing noises when the clutch is disengaged.

- Difficulty shifting gears.

- Increased vibration or shaking, particularly in the clutch pedal or steering wheel.

- Unusual sounds that increase with engine speed.

- Overloading: Vehicles frequently used for towing or heavy-duty applications put more stress on the drivetrain, speeding up the wear on the pilot bearing.

- Contamination: Dirt, moisture, and other contaminants can enter the bearing, causing rust or grinding, which accelerates its failure.

Ignoring a worn pilot bearing can result in misalignment of the transmission, which can lead to more serious and expensive damage, such as the destruction of the ram flywheel 2518 pilot bearing replacement, transmission gears, or even the engine’s crankshaft. Therefore, replacing a worn or damaged pilot bearing as soon as you notice any issues is a wise decision.

Tools and Equipment Needed

Before you begin the process of replacing the pilot bearing in your Ram 2518, it is essential to have all the right tools for the job. This will not only make the task easier but will also ensure that the job is done correctly.

Essential Tools:

- Hydraulic Jack and Jack Stands: To safely lift the vehicle and ensure it is securely supported while you work underneath.

- Socket Wrench Set: To remove bolts and fasteners securing various components.

- Torque Wrench: To ensure that all fasteners are tightened to the manufacturer’s recommended torque specifications.

- Flywheel Puller: In case you need to remove the flywheel to gain access to the pilot bearing.

- Pilot Bearing Puller: This is a specialized tool designed to extract the pilot bearing from the flywheel without causing damage.

- Grease or Lubricant: To lightly grease the new bearing before installation, ensuring it fits smoothly into place.

- Screwdrivers or Pry Bar: For additional help when removing components.

- Hammer and Socket: To tap the new pilot bearing into place without damaging it.

Optional Tools:

- Transmission Jack: This can be useful for easier lifting and supporting of the transmission during removal and reinstallation.

- Clutch Alignment Tool: Used for properly aligning the clutch disc during reassembly.

Having all of these tools prepared will ensure the process goes smoothly and efficiently, reducing the chances of mistakes.

Step-by-Step Guide to ram flywheel 2518 pilot bearing replacement

Now that you are prepared with the necessary tools and knowledge, let’s break down the process of replacing the pilot bearing in your Ram 2518.

Preparing the Vehicle

Safety First: Ensure that the truck is on a stable and level surface. If you’re working on a lift, that’s ideal. Otherwise, use a hydraulic jack to lift the front of the vehicle and secure it with heavy-duty jack stands.

Disconnect the Battery: Disconnect the negative terminal of the battery to eliminate any electrical hazards.

Remove Obstructions: To gain access to the transmission, you may need to remove certain components, such as the driveshaft, exhaust system, or crossmembers. Remove anything that might obstruct your access to the transmission.

Removing the Transmission

Remove the Clutch Assembly: Unbolt the clutch assembly, which includes the pressure plate and clutch disc. Take care not to damage any parts that will be reused.

Unbolt the Transmission: Use your socket wrench to unbolt the transmission from the engine. Be sure to support the transmission with a transmission jack to avoid injury or damage to the transmission.

Slide the Transmission Back: With the transmission bolts removed, carefully slide the transmission back to disengage the input shaft from the ram flywheel 2518 pilot bearing replacement. You should now have clear access to the flywheel and pilot bearing.

Removing the Old Pilot Bearing

Examine the Old Bearing: Inspect the pilot bearing to assess its condition. A worn or damaged bearing should be removed immediately.

Use a Pilot Bearing Puller: This is the most efficient method for removing the bearing. A pilot bearing puller grips the bearing and extracts it from the flywheel with minimal effort. If you don’t have this tool, the grease method (explained below) is a viable alternative.

Grease Method: If a puller is unavailable, fill the cavity behind the bearing with grease. Then, insert a dowel or rod into the center of the bearing, ensuring it fits snugly. Tap the dowel with a hammer, and the hydraulic pressure from the grease will push the bearing out of place. This method is effective but requires caution to avoid damaging the flywheel.

Clean the Flywheel: After the bearing is removed, thoroughly clean the flywheel and surrounding areas to remove any grease, dirt, or debris.

Installing the New Pilot Bearing

Check the New Bearing: Before installation, verify that the new pilot bearing is the correct size and matches the specifications for your Ram 2518. Double-check its alignment and size to avoid installation errors.

Grease the Bearing: Lightly coat the outside of the new bearing with grease.

Align the Bearing: Position the new bearing into the cavity on the flywheel. Make sure it is properly aligned with the transmission’s input shaft.

Tap the Bearing Into Place: Using a hammer and a socket (or a dedicated bearing installer tool), gently tap the bearing into place. Ensure the bearing is flush with the flywheel surface.

Reassembling the Transmission ram flywheel 2518 pilot bearing replacement

Reinstall the Flywheel: Once the pilot bearing is in place, reinstall the flywheel. Be sure to torque the flywheel bolts to the manufacturer’s recommended specifications to avoid any damage or issues.

Reassemble the Clutch: Reinstall the clutch disc and pressure plate. Use a clutch alignment tool to ensure that the disc is correctly aligned with the flywheel and transmission input shaft.

Reattach the Transmission: Carefully lift the transmission back into position. Align it with the engine and rebolt it into place.

Reconnect the Battery: Finally, reconnect the battery and ensure all systems are back online.

Testing the System

Before taking your truck for a test drive, it’s important to check the work you’ve done:

- Check Fluid Levels: Ensure the transmission fluid is topped up and that there are no leaks.

- Test the Clutch: Press the clutch pedal to make sure it feels firm and engages properly.

- Test Drive: Start the engine and engage the clutch to test the transmission’s operation. Pay attention to any unusual sounds, vibrations, or difficulty shifting. A smooth operation means the job was successful.

Common Mistakes and Tips

- Not Using the Right Tools: Ensure that you use the proper tools to avoid damaging the bearing, flywheel, or other components.

- Forgetting to Grease the New Bearing: Greasing the new pilot bearing ensures it slides smoothly into place and reduces friction during initial use.

- Improper Torque Specifications: Always refer to your vehicle’s manual for the correct torque specifications to avoid damaging bolts or components.

- Not Replacing the Pilot Bearing: Skipping the pilot bearing replacement, even if it seems functional, can lead to problems down the line. A worn bearing can damage the transmission, resulting in costly repairs.

Conclusion

Ram flywheel 2518 pilot bearing replacement is an essential part of maintaining the health of your transmission. This simple yet vital task can prevent costly issues down the road and improve the overall performance of your truck. By following the steps outlined in this guide and using the right tools, you can successfully replace the pilot bearing yourself. However, if you’re not confident in your abilities, it’s always a good idea to seek the help of a professional mechanic to ensure the job is done correctly. Regular maintenance is key to keeping your Ram truck running smoothly for years to come.

Post Comment